Overview

Product Details

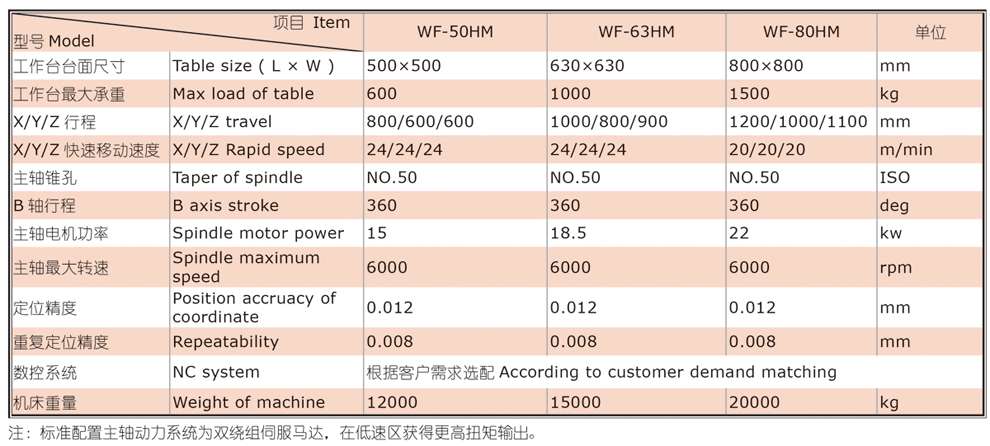

HM horizontal machining center

HM horizontal machining center has the characteristics of convenient use and compact structure. It integrates all functions of the horizontal machining center and advanced technology perfectly. The double exchange worktable is adopted, and Z is suitable for multi process machining such as milling, drilling, boring, stranding, tapping, two-dimensional and three-dimensional curved surfaces of parts with multiple working faces. It has the good performance of completing the box hole system and plane machining in a single clamping process, and can also meet the requirements of turning around and boring the box hole. It is widely used in automobile, internal combustion engine, household appliances, and general machinery industries.

1. The machine tool adopts an integral T-shaped casting bed, gantry column, and hanging box spindle box structure. Triangular stiffeners are arranged inside the machine bed to make the machine bed thick, so that the machine tool can obtain high rigidity and long-term stability accuracy. The heavy stiffeners arranged along the rectangular guide rail of the column greatly strengthen the rigidity of the column, which can ensure that the machine tool still has high accuracy, stability and excellent vibration absorption capacity when the spindle box is located at the upper end of the Y axis.

2. Y-axis double guide system. The design of the machine tool column is similar to precision coordinate boring. The Y-axis composite double guide system on the front and side of the guide rail makes the spindle box contact with the guide rail on seven surfaces, so that the machine tool can cut vertically. At the same time, it has local precision in arc interpolation and profile ironing.

3. Roller type strong heavy load guide rail has similar dynamic and static friction coefficients, no creeping at low speed, high positioning accuracy, and high dynamic response characteristics at the same time.

4. The oil air lubrication system can make the main shaft bearing get constant and reliable lubrication, improve the service life of the bearing, and make the precision of the main shaft stable for a long time.

5. The feed unit adopts double nut ball screw with large diameter, and applies pre tightening at both ends to eliminate accuracy loss caused by thermal elongation.

HM horizontal machining center has the characteristics of convenient use and compact structure. It integrates all functions of the horizontal machining center and advanced technology perfectly. Double exchange worktable is adopted, and Z is suitable for milling, drilling, boring, stranding, tapping, two-dimensional, three-dimensional curved surfaces, etc

Multi process processing, with good performance of completing the box hole system and plane processing in one clamping, can also meet the turning boring processing of box holes, and is widely used in automobile, internal combustion engine, household appliances, and general machinery industries.