Overview

Product Details

Product Description

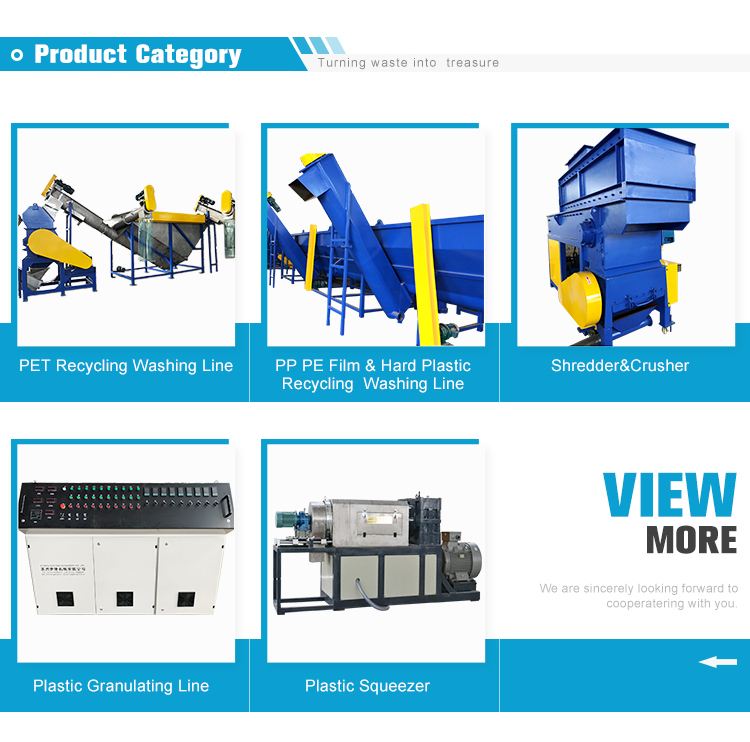

1,This PET bottle crushing, washing and drying production line can wash and recycle waste PET bottle flakes easily, which includes PE/PP labels, PVC labels, paper labels, HDPE cups, glue, mud, beverage leftover, oil, and scrap iron.

2, Equipment at the end of the washing line so that the completely dry flakes can be collected and packed directly after being washed. 3, the whole production line can be designed on the basis of how dirty the flakes are, and make sure of the quality of the final products.

4, Coordinating the production line with follow programmed work (granulating system), and it will make waste and dirty PET bottles to be the PET granule material and in order to producing new PET bottles. The material from this equipment can be put into the granulating machine directly.5, we can supply production line with capacity from 100kg/h to 3000kg/h.

The whole equipment includes parts:

NO | ITEM | DESCRIPTION | SELECTIVITY |

1 | Prewasher | Remove the solid impurity which are water insoluble, such as hand stone, sand, etc. It can also wash bottles' surface. | Optional |

2 | Bale Breaker | It is used in large capacity recycling line, and bottles are compressed in bale. | Optional |

3 | Belt Conveyer | Including the metal detector. | Necessary |

4 | Label Remover | Label removing efficiency, more than 98% | Optional |

5 | Manual Select Platform | Made according to workers' height, supply a suitable plate for selecting the left labels or some other impurity. | Optional |

6 | Belt Conveyer | Conveying the bottles into crusher. | Necessary |

7 | Crusher | With water, the materials of the blade adopt SKD-II or 9CrSi. It has a function of prewashing too. | Necessary |

8 | Screw Feeder | Conveying the flakes into friction washer. | Optional |

9 | Friction Washer | Scrubbing material in high-speed with water. | Optional |

10 | SCrew Floating Washer | Remove few remand paper, sand, label from material based on different density. | Optional |

11 | Screw Feeder | Conveying the flakes into hot washer. | Necessary |

12 | Hot Washer | High temperature stirring washing with caustic soda. Water can be heated by steam or electric. | Necessary |

13 | Screw Feeder | Same as Item 8. | Necessary |

14 | Friction Washer | Same as Item 9. | Necessary |

15 | Screw Floating Washer | Same as Item 10. | Necessary |

16 | Dewatering Machine | High speed centrifuge drying. | Necessary |

17 | Drying System | Electric heating wind drying. | Necessary |

18 | Label Wind Separator | The last left impurity will be separated from flakes by the blower fan. | Optional |

19 | Silo | Store the final material. | Necessary |

20 | Electrical Control Panel | Adopts Siemens and DELIXI as main component. | Necessary |

We can supply production line with capacity from 500kg/h to 3000kg/h.

We have the certification ISO9001:2000 and we are working hard to get the CE certification. So the quality of our products are reliable.

SHIPMENT | 45 working days after receipt of order and down payment |

PAYMENT TERMS | - 30% T/T at sight at the order - 70% T/T at sight before delivery |

PORT OF LOADING | Shanghai, China |

PACKING | Machine will be packing by stretched film and fixed with iron wire in the standard seaworthy wooden case. |

WARRANTY | - Mechanical parts:12 months from delivery - Electric motors:6 months from delivery or manufacture's warranty - Electromechanical components and instruments:6 months from delivery or manufacture's warranty |

Q1: You are a Manufacturer or a Trade Company?A: We are a professional recycling equipments manufacturer.

Q2: When can I get the price?A: I will check the detail immediately and give you the quotation for 30 minutes.

Q3:Could you show me some vidoes and pictures of your equipments?

A:Of course,we are very glad to show you the videos and pictures to let you know more about our equipments.

Q4: What is the time for delivery?A: Normally,30~45 days for production.

Q5: What is the payment terms?A: 30% deposit and the balance to be paid before shipment,we will take photo show details when goods ready.

↓ ↓ ↓ ↓ ↓ ↓ ↓ ↓

Wish You Have A Pleasant Purchasing Time!

Pls Click “Contact Us”