Overview

Product Details

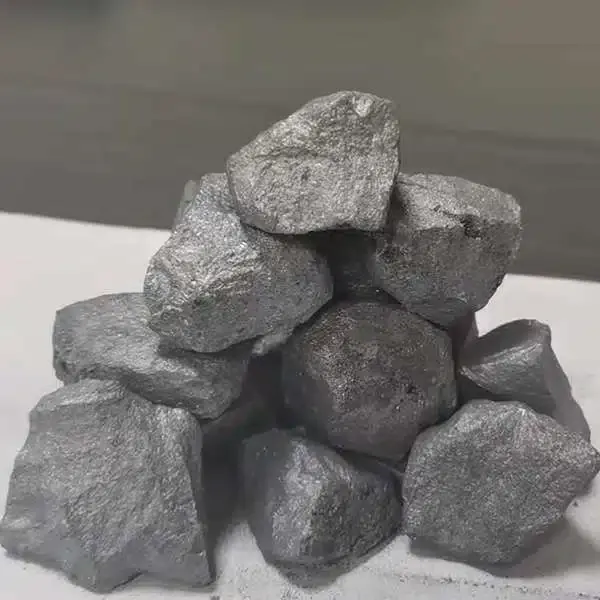

Find a wide variety of casting materials,refractory material at Fuyaochang. Choose from our selection of carbon steel alloy,alloy of carbon,alloy containing carbon,silicon products,ferroalloys and receive fast dispatch.

Spheroidizing agent, also known as rare earth magnesium ferrosilicon alloy, is mainly used for nodular cast iron. After adding molten iron, it can play the role of spheroidization, desulfurization and degassing, improve the purity of casting water, and act with arsenic, zinc, lead and other low melting point impurities to form compounds with low melting point that do not melt in iron. Eliminating these impurities can prevent interfering elements from damaging spheroidization. Application scope of spheroidizing agent: all kinds of nodular iron castings Characteristics of spheroidizing agent: strong spheroidizing ability, stable reaction, high absorption rate and no worry of recession 1. Stable composition and small fluctuation; 2. High alloy purity and low magnesium oxide content; 3. The microstructure of the alloy is dense, and it is not easy to float during spheroidization; 4. The composition and particle size can be accurately controlled according to requirements. Application method of spheroidizing agent: 1. The ratio of height to inner diameter in the spheroidizing treatment package (dam type) shall be greater than 1.5 to facilitate the absorption of magnesium. 2. The temperature of spheroidized molten iron is 1460 ℃ --- 1550 ℃ Put spheroidizing agent, inoculant, covering agent, iron pin and steel plate in turn on the side of the treatment package back to the molten iron. It should be noted that the spheroidizing agent and the covering should be moderately tight (the covering should be changed appropriately according to the molten iron temperature and reaction intensity) 3. Since the situation of each manufacturer is different, it is necessary to flexibly grasp the reasonable addition amount to achieve the use effect of * * *.