Overview

Product Details

Product Information

Size and shapes:

Custom production according to drawings

Application

Graphite heating components are widely applied in high temperature industrial furnaces like vacuum furnace, resistance furnace, induction furnace, sintering furnace, hot pressing sintering furnace, soldering furnace, ion nitriding furnace, Tantalum niobium

smelting furnace, annealing furnace, quenching furnace etc.

Material:

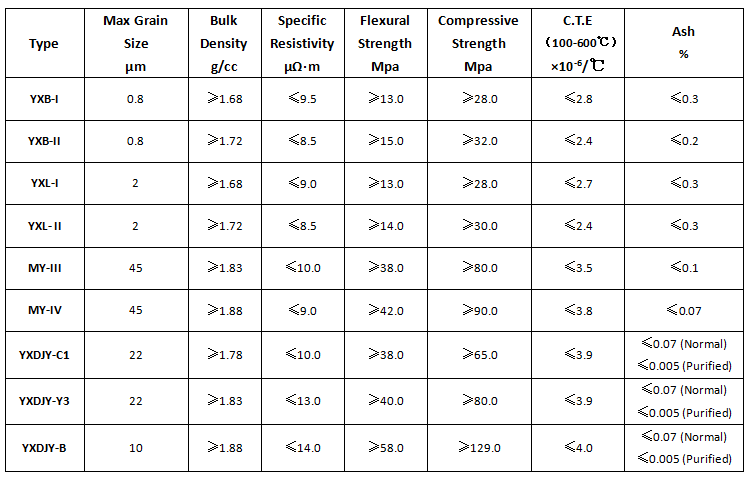

High Purity, high strength extruded or isostatic graphite material with uniform structure will be proposed by our experienced and professional engineers based on customers' specific application conditions, in order to be optimally cost effective.

If the technical specifications you required are not among the following list, we can custom produce according to your requirements.

If you are not sure of which grade to select, we can choose appropriate material according to customer’s application (working condition) based on rich experiences in graphite applications.

Typical Technical Specifications:

Product Display

Advantages

A. High temperature resistance as high as 3000 degree and long service life.B. High strength and no strength reduction even at temperture of 3000 degreeC. High purity, low ash content as 0.1%, or even purified to 50ppm or 10 ppm at requestD. Good structure uniformity and continuously stable quality.E. Chemically stable property and no reaction with treated substances, and graphite will not be sticked to the treated products.F.Good thermal conductivityG. Graphite heating parts design service available.

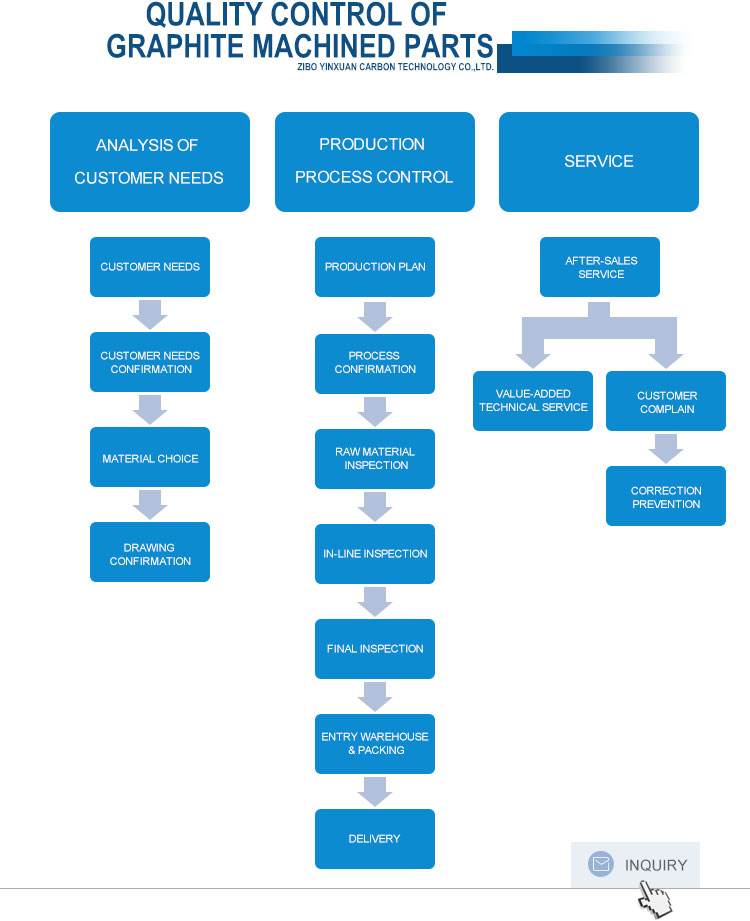

1.Zibo Yinxuan controls the quality in whole procedure according to ISO standard and ensures dimensions accuracy required by customers for all kinds of crucibles.

2.Zibo Yinxuan owns proprietary technologies of anti-oxidation and impermeability to improve graphite life and performances.

3.Based on smelting process and purity requirements, Zibo Yinxuan proposes cost-effective graphite material and graphite crucibles application solutions by graphite professional engineers with extensive graphite knowledge and rich experiences in graphite production and deep study of graphite applications. 4.Thorough, prompt and professional services. All emails replied within 12 hours.

5.Technology driven team with principle as truth, accuracy and customer-orientation.

Company Profile

Exhibition

Related Products

Packing & Shipping

Packing Details | 1. Thermal conductivity graphite are packed in plywood cases with 15mm min thickness boards. 2. Each piece of thermal conductivity graphite is separated by 10~15mm thickness foam to avoid touch and abrasion. 3. Tightly packed to avoid thermal conductivity graphite moving during transportation. 4.Custom packages are also acceptable at request. |

FAQ

Q1: How does Zibo Yinxuan Assure Quality?

A1: a. Zibo Yinxuan manufactures graphite blocks with strict quality control on ISO 9001: 2015 standard.

b. Graphite material is inspected and evaluated for assurance before machining in our own lab.

c. Specially-assigned inspector inspects measurements during machining.

d. Second time measurements inspection before packing.

e. Safe package will be inspected before shipment.

Q2: What After-sales Service Could Zibo Yinxuan Provide?

A2: a. After graphite products leave from our factory, our logistic staff will closely track the shipment until safely delivered.

b. During application, our business and technical staff are available for you. Any emails will be replied within 12 hours, and solutions given within 24 hours.

c. For confirmed quality claim, Zibo Yinxuan will assume the responsibility by replacing with

new products or payment compensation.

Q3: What’s Zibo Yinxuan’s Specialty?

A3: a. Zibo Yinxuan supply from graphite material to finished graphite parts with quality control

in whole procedure.

b. Zibo Yinxuan can do anti-oxidation, impermeability, wax & resin impregnation, purification treatments to graphite finished products, to improve graphite life and performances.

c. Zibo Yinxuan team is with strong consciousness of service to customer from product quality control, package, delivery time to after sales service.

d. Zibo Yinxuan is trustworthy graphite manufacturer with integrity.

Q4: What Is Shipping Time?

A4: Generally in 10~20 days since order confirmed.

We have high flexibility on delivery time, for urgent orders, we will do everything possible to

deliver in shortest time.

Q5:What Is The Export Percentage in Zibo Yinxuan Whole Business?

A5: Over 95%. Main customers distribution: Korea, Japan, Indonesia, Malaysia, Taiwan, South Africa, Russia, Austria, Germany, UK, Spain, France, Italy, Luxemburg, USA, Australia, New Zealand, Argentina etc. Over 95%. Main customers distribution: Korea, Japan, Indonesia, Malaysia, Taiwan, South Africa, Russia, Austria, Germany, UK, Spain, France, Italy, Luxemburg, USA, Australia, New Zealand, Argentina etc.

Trading Area

Global