Overview

Product Details

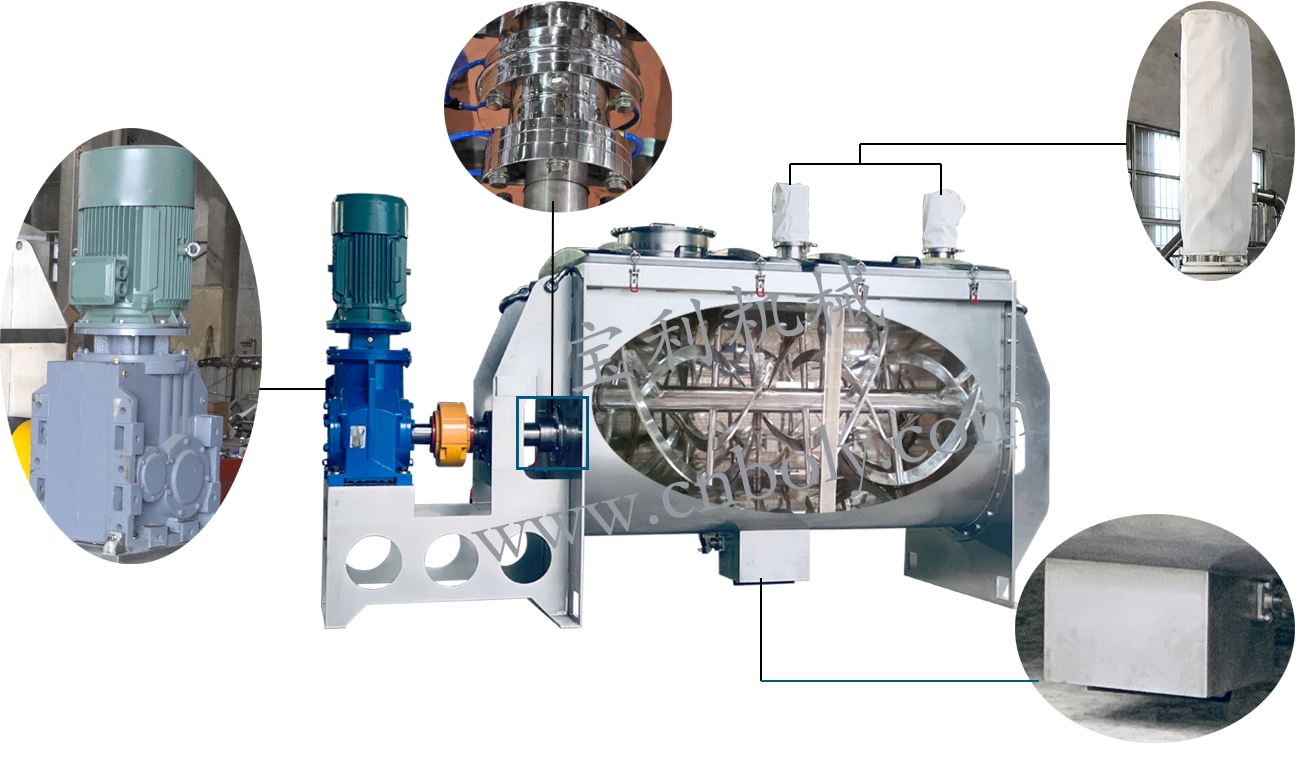

Industrial powded food blender mixing machine powder mixer machine

Features

1.Ribbon mixer 2. CE, ISO, SGS, BV approved; 3. Wide application in: Powder and liquid mixing (like Food, Pharmaceutics; Agriculture; Dyestuff; Chemicals), small fiber, and paste with low viscosityGeneral IntroductionB series Ribbon Mixer is a pioneer product researched and a new high-efficiency mixer. It is widely usedin the solid-solid (powder material) and solid-liquid (powder material& fluidity material) mixing in the field ofchemical industry, pharmacy, foodstuff industry, etcThis is a horizontal Ribbon Blender ,designed to mix all kinds of dry powder .It consists of one U-shaped horizontal mixing tankand two groups of mixing ribbon: outer ribbon displace the poweder from the end to the center and inner ribbon move the powderfrom the center to the ends .This counter-current action results in homogeneous mixing.The cover of the tank can be made as openin order to cleaning and change parts easily.

Model | Main Structural Dimensions(mm) | Volume | Max loading | Speeding | Machine weight | Total Power | ||||||

L1 | W2 | H1 | H2 | L | KG | RPM | KG | KW | ||||

JB-300 | 1915 | 850 | 1000 | 50 | 300 | 180 | 65 | 600 | 4 | |||

JB-500 | 2510 | 1000 | 1275 | 50 | 500 | 300 | 65 | 900 | 7.5 | |||

JB-1000 | 2980 | 1120 | 1380 | 50 | 1000 | 600 | 48 | 1300 | 11 | |||

JB-1500 | 3160 | 1420 | 1570 | 50 | 1500 | 900 | 48 | 1600 | 15 | |||

JB-2000 | 3360 | 1450 | 1625 | 50 | 2000 | 1200 | 35 | 2000 | 15 | |||

Technical Parameters

Standard configuration1. Drive Unit: Cycloid reducer or gear reducer2. Motor brand: Siemens (made in China)3. Gear box brand: Chinese Famous brand (Huaxing)4. Bearings: Chinese Famous brand 5. Discharging valve: pneumatic flap valve (no dead angle when mixing). 6. Main Shaft SealAir-purged seal and stuffing seal for powder materialMechanical seal for liquid material7. Voltage and Hz380V 3Phases 50hz or in accordance with it in the using place8. Top CoverCould be fully open so as to clean, with safety grid and limit switch to make sure safety operation for workers9. Normal duty type: start the mixer first and then load the material10. Surface treatment: painting, polishing, passivation, blasting, acid-picking and so on11. Packing in pallet or wooden case

Additional configuration1. Driven unit: Many worldwide famous brands are for option: SEW, ABB, Siemens and so on2. Bearings: NSK/TNT and so on 3. Heating/cooling jacket: water, oil, steam as the cooling or heating medium 4. Spraying system5. Heavy duty type ( loading your material into the mixer first and then start the mixer)6. Platform: we build the platform for you or we design it and you build it locally7. Mixing system: including packing machine, bucket elevator, Sieve, screw conveyor and so.8. Customizing according to client's specific requirement 9. High speed choppers can be added inside the mixing tank to promote the mixing effectMajor parameters for technology selection1. powers name and character (mesh and density)2. output per batch3. stainless steel 304/316LL or carbon steel4.the electrialenviroment in machine's using place

Mixers need to be customized according to the different cases, the cases are as below:

1. Agglomerated material larger than 5mm is contained in the raw material2. Bulk density of the raw material bigger than 3kg/l3. Materials that are easy to get damp and not allowed to be exposed to the atmosphere, the mixer need to be vacuumized or negative pressure4. Fill compressed air to the mixer barrel, and keep the pressure5. Material with a large friction coefficient, mixer need to do a special Wear-resistant surface treatment6. Material is not allowed to contact with the metal surface during mixing process 7. Mixer need to be heated up to 200 Celsius degree8. Heavy duty (loading material into mixer before turning on it) is required.

Our company locates at Wuxi city, very near Shanghai City and it only takes 30 minutes to get to our city by train from Shanghai.1) We are golden supplier on overseadia with a history of more than 9 years.And our factory's history is more than 13 years.2) We have CE certificate, ISO,BV...etc.3) Each year,we takes part in a lot of Expos :for example, FIC, CPHI, API...etc

Wish you will like this machine.Could you tell me some more details ,then i will recommend you more suitable type machines. 1)What material you want to mix? 2) What capacity you expect ? (kg/batch or litre/batch ) 3) What voltage you want? For example,380V 50hz 3p; 440V 60Hz,3p; 220V... (We only provide 3P, because our machines are all for industrial use,not for family.) 4) What material of the equipment you want? usually we adopt all stainless steel 304. You can also choose A SUS304 B SUS316 C contact part SUS316 , other parts SS 304. |

Transaction History |

Pre-Sales Service

* Inquiry and consulting support with 24 hours* Sample testing support. * View our Factory.

After-Sales Service

* Instructing how to install the machine, insutructing how to use the machine. * Engineers available to service machinery overseas.

Jiangyin Baoli Machinery Manufacturing Co.,Ltd is a manufacturing-oriented enterprise founded in 2004.

After more than ten years of unremitting efforts, our company mainly applicated in Crushing/Mixing/Coneying/Sifting/Drying equipments from all over the world.

Why choose us?* 24 hours online email service.* Our principle: high honest, quality,service* We are a big factory with rich experience and technology, engaged in the machinery industry. Best quality controls best services.

Why your machine similar with other supplier?We are manufacturer and had been in this industry for many years. We design machines by ourselves with advanced technology. Appearance just a part of machine, Service and quality is more important than it.I'm new in our industry, but I'm planning to set up a factory, What can I do?We can suggest customer the most suitable machine according to their formula, Raw material. Manufacturing- Installation- Training- Maintenance- Technical Support. We can introduce you supplier of raw material, bottles, labels etc. We could take you to our customer's factory to learn how they produce. We could customize machines according to your real need, We could send our engineer to your factory to install machines and train your worker of Operation and maintenance. Any more requests. Just let us know.What kind of machines can you supply to customer?We could offer various kinds of machines and whole production line.

Our company specialized in making grinding machines,mixers and sifters....

If you want to know about our machines ,you can contact me at any time.