Overview

Product Details

Twin screw extruders for color caco3 filler masterbatch machine

Brief introduction:

Co-rotating parallel twin screw extruder for masterbatch, its barrel, screw adopts cordwood combination method, according to Material Processing System and technical requirement, its L/D, screw arrangement, number of venting and electric control can all realize multi-function and Multi purpose for materials.

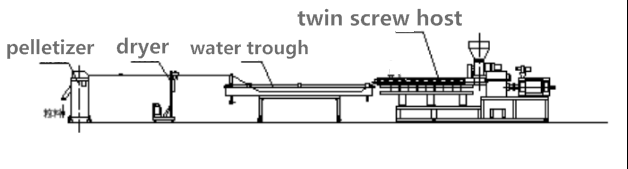

twin screw extruder for masterbatch is extrusion strand pelletizing, consisting of parallel twin-screw extruder and corresponding auxiliary granulation.

The gearbox is high torque design, implement smooth operation, low noise.

Application for color masterbatch & filler masterbatch twin screw extruder:

1. Master batch and color master batch:

PP/PE/ABS+Caco3/Sio2(silicon dioxide)/talc(chalk)/carbon black

2. PP/PA/PA6/PA66/PA10/PA1012/ABS/PBT/PET/POM+glass fiber/carbon Fiber/iron fiber

3. PBT, PET recycling

4. EVA

|

Model |

Diameter(mm) |

L/D |

RPM (r/min) |

Power (Kw) |

Torque(N.m) |

T/N |

Capacity (Kg/h) |

| SJSL-20 | 20 | 32-44 | 600 | 5.5 | 30 | 4.8 | 6.5-15 |

| SJSL-36 | 36 | 32-48 | 600 | 15 | 115 | 4.2 | 30-75 |

| SJSL-51A | 51 | 32-52 | 500 | 45 | 405 | 5.1 | 100-200 |

| SJSL-51B | 51 | 32-52 | 600 | 55 | 415 | 5.2 | 150-25 |

| SJSL-63A | 63 | 32-62 |

400 |

55 | 620 | 4.4 | 160-250 |

| 500 | 75 | 675 | 4.8 | 200-300 | |||

|

SJSL-63B |

63 | 32-64 |

600 |

90 | 675 | 4.8 | 225-375 |

| 800 | 110 | 620 | 4.4 | 300-500 | |||

| SJSL-75A | 72 | 32-64 |

400 |

90 | 1015 | 4.7 | 225-350 |

|

500 |

110 | 1005 | 4.6 | 300-550 | |||

| SJSL-75B | 72 | 32-64 |

600 |

132 | 990 |

4.6 |

400-650 |

| 800 | 160 | 900 | 4.2 | 480-800 | |||

| SJSL-92A | 92 | 32-64 |

400 |

250 | 2815 | 5.9 | 650-1050 |

| 500 | 2250 | 4.7 | 750-1250 | ||||

| SJSL-92B | 92 | 32-64 |

600 |

280 | 2365 | 5.0 | 900-1500 |

| 800 | 2250 | 4.7 | 1200-2000 | ||||

| SJSL-135A | 135 | 32-48 | 400 | 315 | 6190 | 4.6 | 1500-2500 |

| SJSL-135B | 135 | 32-48 | 500 | 400 | 6750 | 5.1 | 200-3500 |

Process: Plastic raw material will be melting, compounding, homogeneity plasticizing, etc. inside twin screw extruder then come out from die head as shape of strip, dryer work for cooling those plastic strips, lastly pelletizer cut strips to granules.

Photo of color masterbatch & filler masterbatch twin screw extruder:

Twin screw extruder Cooling by water

Blower works for dry out plastic Cutting plastic into granules

FAQ

1. Are you a factory or trading company?

Both.

2. Where is your factory located? How can I visit there?

Our factory is located in industrial centralized area of Moling town, Jiangning, Nanjing, China.

(1) You can fly to Nanjing Airport directly. We will pick you up on Nanjing Lukou International airport;

(2) You can fly to Shanghai Pudong International Airport then come to Nanjing by High-speed railway, then we will pick you up in the railway station.

3. What's your advantages?

(1) Excellent quality control

(2) First-class service

(3) Professional Tech. and R&D team

(4) Quick manufacturing time

(5) Quite competitive price

4. How long is the delivery time?

Under normal conditions, products are delivered within 35 days.

5. How can I know the stauts of my order?

We will send you photos and videos of your order at different satge in time and keep you informed of the latest information.

6. how long is the warranty?

We can offer one-year warranty for the whole machine.