Overview

Product Details

Product Description

Product description

Benu epoxy flat coating floor paint is a two-component high-performance, thin-coat type, solvent-free epoxy floor coating produced with high-quality imported raw materials. The painted surface is smooth and beautiful, durable. It is suitable for the use of thin coating type topcoat in the floor coating system.

Product Usage

Concrete floors in manufacturing workshops and garages, offices, shopping malls, warehouses and other places in the electrical, electronics, food, medicine, chemical, machinery and other industries.

Test projects | Unit | Index | ||

Pencil hardness | — | ≥H | ||

Impact resistance | Kg·cm | 50 | ||

Abrasion resistance(750g/500r) | g | ≤0.03 | ||

Adhesion (cross-cut method) | Level | 1 | ||

Drying time | Surface dry | h | ≤4 | |

Full dry | h | ≤24 | ||

Resistance to 10% sulfuric acid | 7 days | No change | ||

Resistance to 10% sodium hydroxide | 7 days | No change | ||

Resistant to 3% salt water | 7 days | No change | ||

All tests (except the drying time) are performed after curing for 7 days (25℃)

Instructions:

1. Mixing: A:B = 4:1, stir well after mixing.

2. During construction, the curing temperature is 10-35℃, and the relative humidity is less than 80%, otherwise construction is prohibited. Please use the winter type below 20℃, and the summer type above 20℃; the moisture content of the concrete base surface should be less than 6%. The construction site should be ventilated and dust-free, but there should be no strong wind, so as not to bring in dust and affect the apparent effect. This product is not suitable for locations exposed to direct sunlight or where the intensity of ultraviolet light is relatively high.

Usable time: about 30 min (25℃); the higher the temperature, the shorter the useful life after mixing. When the ambient temperature is higher than 35℃, construction is not suitable.

3. Theoretical consumption: 0.15~0.3kg/m2 (adjusted according to the situation);

4. Recommended thickness: 0.2~0.3mm (dry film thickness);

5. Construction method:

Roller coating Large area construction use, using medium long woolen roller

Spraying Use conventional spraying or airless spraying equipment

Brushing It is recommended to use it on a small area, and a soft brush should be used

Construction method | Main material | Auxiliary material | Reference dosage | |||||

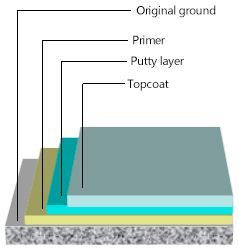

Base surface treatment | Polish the base surface, repair defects, clean and dry | — | — | — | ||||

Primer layer | Roll coating epoxy primer | BN-30# | — | About 0.15Kg/m2 | ||||

Putty layer | Use epoxy intermediate coating material to mix quartz powder or double fly powder to scrape putty layer | BN-601 | Quartz powder or double fly powder | 0.10Kg/m2 one pass | ||||

Topcoat | Roll coating or spraying epoxy top coating material | BN-801 | — | 0.15-0.18Kg/m2 | ||||

● Coating thickness: generally 0.2mm-0.5mm | ||||||||

Company Profile

Our Factory

Certificate

FAQ

Trading Area

Global