Overview

Product Details

glass fiber partition wall mold for fiber cement board making machinery

EPS Cement Sandwich Panel is a kind of lightweight energy saving wall material, which uses cement calcium silicate or reinforced calcium silicate board as face panel, filled with cement, Expanded Polystyrene (EPS) foam particles as core material and forming by one time compound.

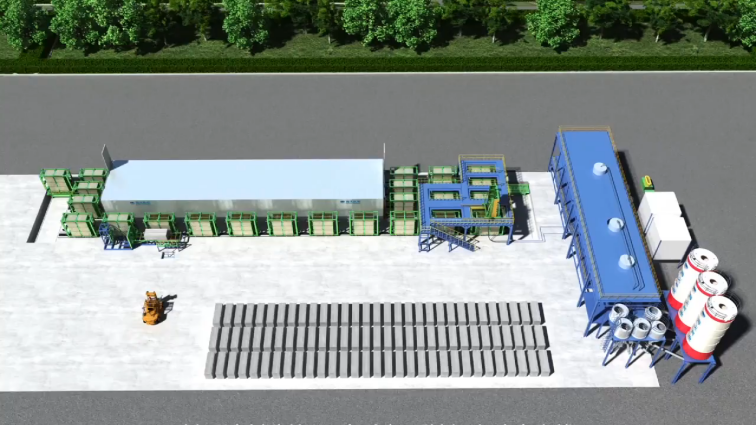

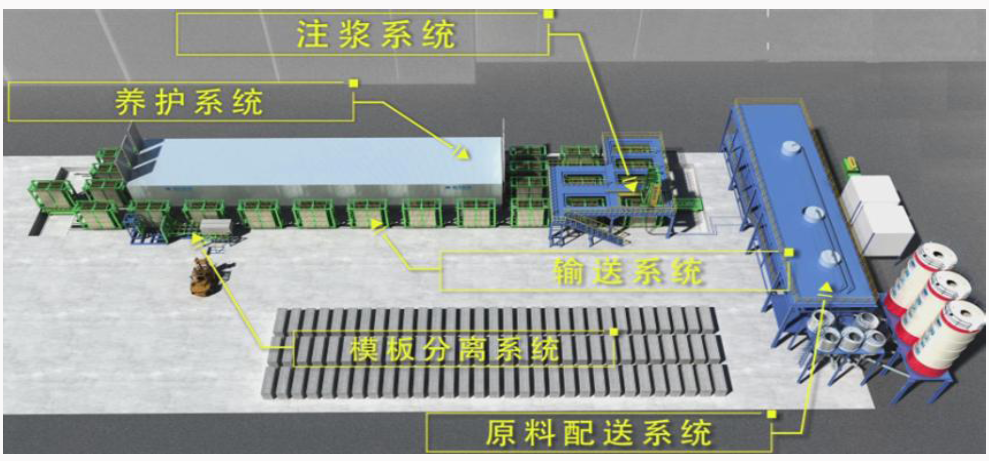

Automatic lightweight eps cement wall panel line

The EPS lightweight panel production line mainly have these parts foaming system, storage system, conveying system, measuring system, mixing system, casting system, demolding system. Demoulding, 20panels/time. So can save a lot of your labor cost.

After installation and commissioning, we will provide technical formula suitable with client's demand, ensuring clients can produce qualified finished products. Additionally, we will help local experienced engineers for one year to master the production process.Our professional sales team, designing team, manufacturing team, installation team, process team, service team, promise you a 100% perfect project.

Main system of eps cement sandwich panel production line:

1.Mixing system (include mixer, platform);

-Cement and flyash will be metering and feeding into the mixer by cement screw conveyor pump, save labor and environmentally . -Sand (or ceramsite /slag /pumice stone other agregate) and additives will be feeding into the mixer by lifting hopper.

1)Double-shaft mixer;

Capacity available :1.2/1.5/2.0/2.5/3.0/3.5 sqm Introduce:the mixer capacity is related to the mould car quantity. Features: the double shaft is to blend the raw material more even ,also save time .

When mould car qty over 10 units, we recommend to use the secondary mixing mixer. This can save time of 01st mixer, improve efficiency.

2)Platform

-Measuring platform,-Mixing platform (necessary),-Casting platform (necessary),-Electric control cabinet platform ,-Auxiliary Platform /Calcium Silicate Board installation platform ps:Besides necessary platform , other platform we can equip as client requirement .

2.Material convey and feeding system:

Use industrial hose pump as grouting power, just need to connect a hose, one worker can easily finish the grouting work. High efficiency and clean at site.

3.EPS foaming system(include boiler, eps foaming machine);

Boiler supply heat, and eps foaming machine foam EPS particales into requried size.

Customer can also choose to buy EPS foam particales locally, to save equipemnt investmetn on this part.

4.De-molding machine:

High automatic level and just need one worker to operate the machine, panels in the whole mold car can be de-mold in several minutes! No damage to the eps sandwich wall panel, high efficiency.

5.Curing system

EPS Cement Sandwich Panels Applications:

-Non-load bearing interior & exterior wall panels, partition wall panels, floor panels, roof panels.

-Bathrooms, kitchens, garages, basements, prefabricated houses, family homes, dormitories, residences, apartments, luxurious villas, factory warehouses, production workshops, auxiliary plants, hotels, bars, shopping malls, restaurants, schools, hospitals, airports, etc.

non-load bearing parition wall panels in prefab buildings:

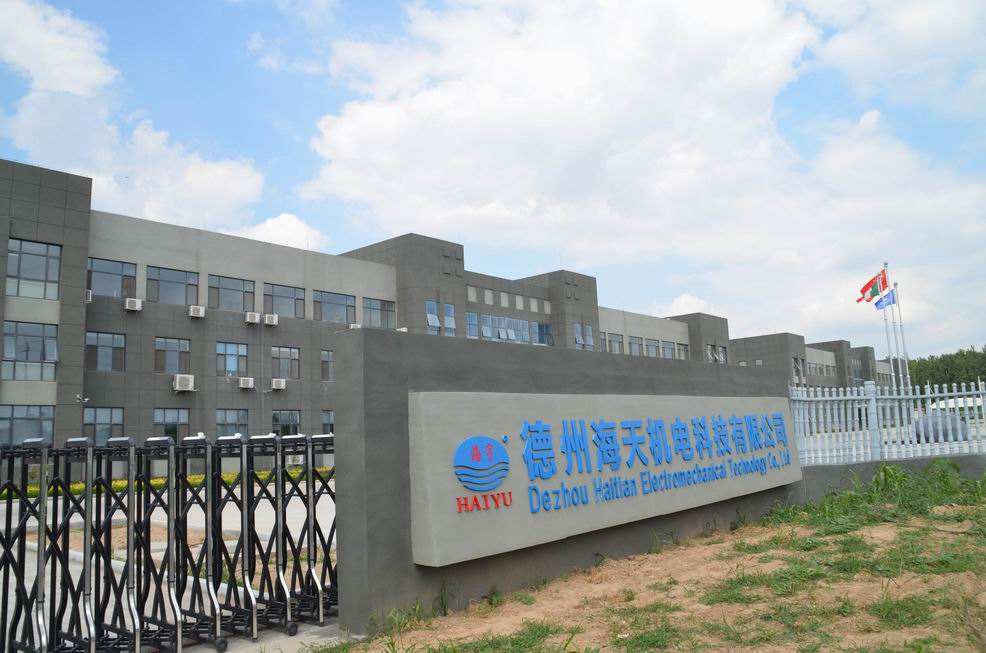

Dezhou Haitian was founded in 1997. We have obtained 20 China national patents, products approved ISO9001:2008 certificate, CE certificate and EU Customs Union CU-TR certificate. For the past several years Haitian has been rated "AAA grade quality and integrity of Chinese brands". We are also the Vice President Enterprises of “China National Precast Concrete and Cement Products Association”

Our main products:

1. Multi-functional Slip former production line2. Precast concrete Moulds (tilt table mould, staircase mould, beam column mould, box culvert mould etc)

3. Pushing vibration type hollow core slab machine

4. Precast fence post machine

5. Precast concrete beam/lintel machine

6. Precast concrete t beam/H beam machine

7. Precast concrete boundary wall panel machine

8. Extruder wall panel machine9.HLJ Vertical type Wall Panel Molding Machine10. HFJ Composite insulation Wall Panel/ Insulation block production line

Welcome to visit our factory!

key words: glass fiber partition wall mold for fiber cement board making machinery