Overview

Product Details

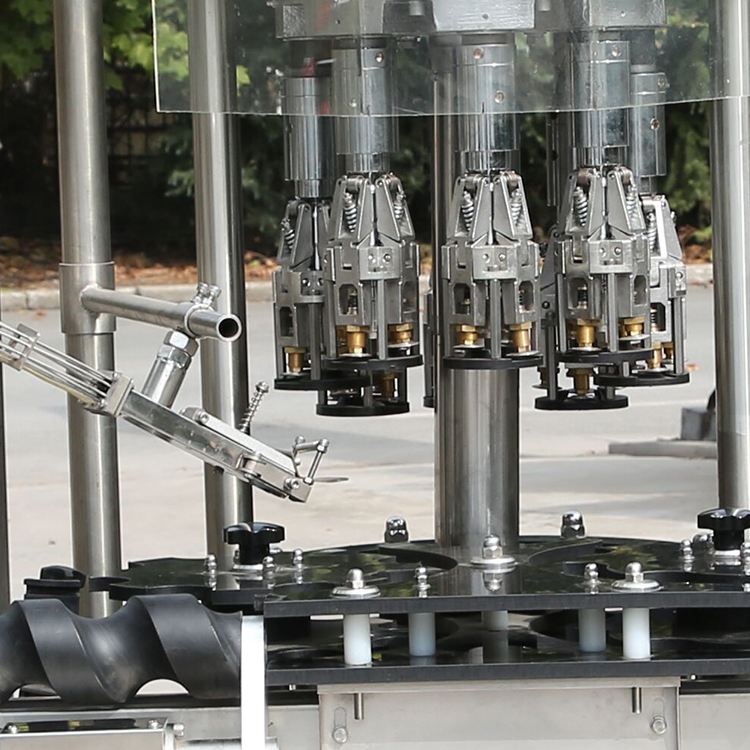

Stelvin screw cap capper, ropp capping machine for glass bottle

Product name | Aluminum cap sealing machine |

Capper head quantity | 1/4/6/8/12 |

Material | SUS304 |

Suitable bottles | glass bottle/aluminum bottle |

Bottle height | 140-320mm |

Bottle mouth Dia | 20-32mm |

Bottle dia | 60-90mm |

Production capacity | 2000-12000 bottles per hour |

Product Information

1.Sealing tight:

no cracks, no scratches, tight bottom sealing.

2.Wide adaptability:

the sealing head can choose German flat swing head or four wheel balanced lever head.

3.High degree of automation:

with automatic cover management and automatic cover hanging function, can be equipped with automatic cover loading device,

4.Long service life:

the sealing wheel is made of special material and treated with wear resistance.

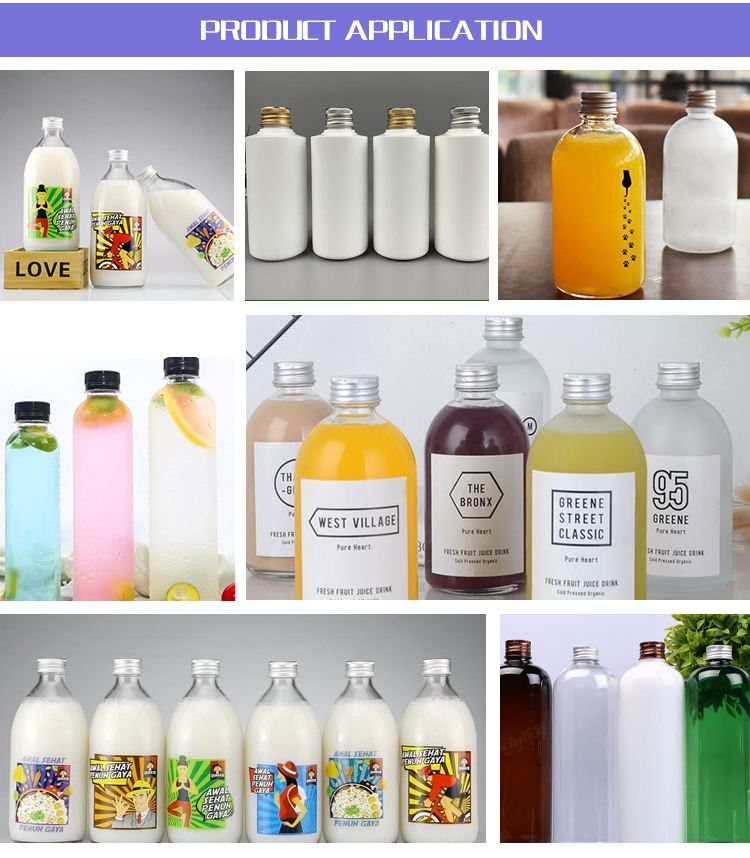

Product Application

Recommend Products

Company Profile

Located in the centre of Shandong Province, Qingzhou Tongda Packaging Machinery CO., Ltd. has an international standardised plant of 12,000 square meters with 100 dedicated members of staff. We are a professional manufacturer of liquid packaging machinery that integrates research, manufacture, sales, and service. Our products are widely used in filling all kinds of liquids, such as liquors, wines, fruit wines, soft drinks, liquid seasonings, edible oils, oral liquids, enzyme, liquid fertilizers, veterinary medicines, diesel exhaust fluids (AdBlue), windshield washer fluids and detergents.

Since our establishment, we have been introducing advanced technology and experts into the research and development of new products with leading concepts, practical functionality, and high quality. With more than 20 years’ experience, now we have formed a complete set of liquid filling and packaging equipment including bottle washing, bottle filling, bottle capping, bottle drying, bottle labelling, carton-opening, boxing, carton-sealing, coding, and water treatment machines. All our products could be used either stand-alone or as parts of filling lines that are distinguished by their high compatibility with a wide range of bottle types, accurate filling, easy cleaning, and simple maintenance. Our customer favoured ‘fully automatic intelligent induction filling line with step-less speed control’ is especially suitable for mass productions and is customisable upon request - thanks to our dedicated teamwork and professional research and development capability, we can reliably design and modify our standard products according to customers’ various needs.

Certifications

Exhibition

Product packaging

FAQ

1. who are we?We are based in Shandong, China, start from 2010,sell to Mid East(00.00%),South America(00.00%),Southeast Asia(00.00%),NorthAmerica(00.00%),Oceania(00.00%),Southern Europe(00.00%),South Asia(00.00%),Eastern Europe(00.00%),Eastern Asia(00.00%),NorthernEurope(00.00%),Domestic Market(00.00%). There are total about 51-100 people in our office.2. how can we guarantee quality?Always a pre-production sample before mass production;Always final Inspection before shipment;3.what can you buy from us?Liquid Filling Line Machine4. why should you buy from us not from other suppliers?We are manufacturer of filling machines such as rinser,filler,capper,labeler etc.We also supply production line solutions.5. what services can we provide?Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian

Trading Area

Global